Industrial processes are currently experiencing their fourth revolution. The entire production process is connected and equipped with sensor technology, which makes huge amounts of data available. Workers are not only supported by technical visualization and information processing, but parts of the decision-making processes are even carried out independently with the help of AI systems. The large amount of data and the fully automated process pose new challenges for mathematics, but offer unprecedented opportunities for optimization algorithms, not only in the optimization of individual production steps, but across the entire value chain.

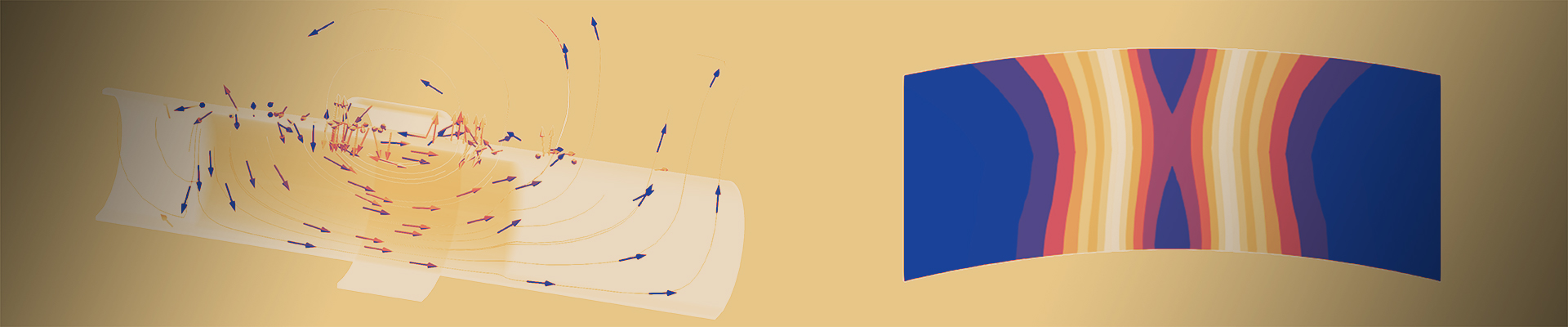

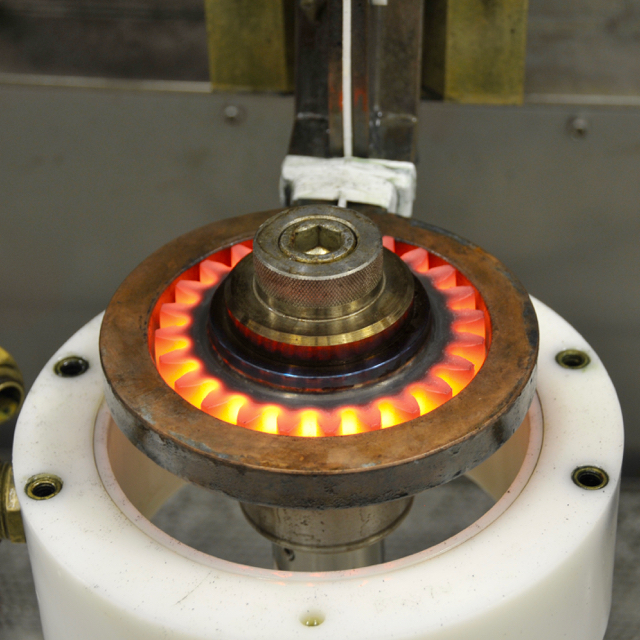

Optimal multi-scale Structure for a 3D printed Beam |  Induction heat treatment of a gear |

In various application projects at WIAS, simulation and optimal control for various production processes, e.g. in the field of steel production and processing, have been investigated. The focus here is on the efficient simulation of processes and the determination of optimal process parameters, which in practice can usually only be determined with the help of time-consuming and cost-intensive experiments. The applications here include: The induction hardening of gears, inductive heating before steel cutting, or inductive welding of tubes.

Steel is also used in new production techniques, such as 3D printing using SLM (Selective Laser Melting). Such additive manufacturing processes enable completely new multi-scale structures whose topology must be optimized with regard to strength throughout the entire printing process or with regard to multi-scale effects. In the production of roses, natural predators of pests are used as environmentally friendly pesticides. Their optimal control can be modeled by the optimal control of partial differential equations.

Simulatiion and optimization of industrial processes is an integral part of different third-party funded projects at WIAS. Within one MATH+ project, the modelling and optimization of weakly coupled minigrids under uncertainty is investigated. In another MATH+ project, anisotropic electrokinetic materials are modelled, analyzed and optimized for the use in so-called "Lab-on-a-chip" devices, which can help to facilitate the access to laboratory functions.

Research Group 4 coordinates a special interest group in the European Consortium for Mathematics in Industry (ECMI) on "Math for the Digital Factory".

The main objectives are

- reconfigurable, adaptive and evolving factories capable of small scale production

- high performance production, combining flexibility, productivity, precision and zero defect

- energy and resource efficiency in manufacturing.

All of these goals require a thorough modelling of all aspects of the process chain together with a multi-scale simulation and optimization of complex production processes.

WG-DOC focuses on robust and scalable machine learning and computational optimization algorithms. On the one hand, robustness and data distribution shift issues in machine learning are addressed, which contributes directly to more resilient optimization techniques. On the other hand, interfacing dynamical systems with machine learning is of interest, particularly through optimal transport theory and kernel methods.

The following application-oriented projects dealt with the simulation, optimization and optimal control of production processes in the last years:

- SPP 1886: Multi-scale failure analysis with polymorphic uncertainties for optimal design of rotor blades,

duration: 01/01/2017 - 31/12/2022

Link - MIMESIS: Mathematics and materials science for steel production and manufacturing,

duration: 01/10/2015 - 30/09/2019

Link

Publications

Monographs

Monographs

-

M. Hintermüller, T. Keil, Chapter 3: Optimal Control of Geometric Partial Differential Equations, in: Geometric Partial Differential Equations: Part 2, A. Bonito, R.H. Nochetto, eds., 22 of Handbook of Numerical Analysis, Elsevier, 2021, pp. 213--270, (Chapter Published), DOI 10.1016/bs.hna.2020.10.003 .

-

M. Hintermüller, M. Hinze, J. Sokołowski, S. Ulbrich, eds., Special issue to honour Guenter Leugering on his 65th birthday, 1 of Control & Cybernetics, Systems Research Institute, Polish Academy of Sciences, Warsaw, 2019, (Collection Published).

-

M. Hintermüller, M. Hinze, Ch. Kahle, T. Keil, Chapter 13: Fully Adaptive and Integrated Numerical Methods for the Simulation and Control of Variable Density Multiphase Flows Governed by Diffuse Interface Models, in: Transport Processes at Fluidic Interfaces, D. Bothe, A. Reusken, eds., Advances in Mathematical Fluid Mechanics, Birkhäuser, Springer International Publishing AG, Cham, 2017, pp. 305--353, (Chapter Published), DOI 10.1007/978-3-319-56602-3 .

-

L. Ghezzi, D. Hömberg, Ch. Landry, eds., Math for the Digital Factory, 27 of Mathematics in Industry / The European Consortium for Mathematics in Industry, Springer International Publishing AG, Cham, 2017, x+348 pages, (Collection Published), DOI 10.1007/978-3-319-63957-4 .

-

P. Deuflhard, M. Grötschel, D. Hömberg, U. Horst, J. Kramer, V. Mehrmann, K. Polthier, F. Schmidt, Ch. Schütte, M. Skutella, J. Sprekels, eds., MATHEON -- Mathematics for Key Technologies, 1 of EMS Series in Industrial and Applied Mathematics, European Mathematical Society Publishing House, Zurich, 2014, 453 pages, (Collection Published).

-

B. Denkena, D. Hömberg, E. Uhlmann, Mathematik für Werkzeugmaschinen und Fabrikautomatisierung, in: Produktionsfaktor Mathematik. Wie Mathematik Technik und Wirtschaft bewegt, M. Grötschel, K. Lucas, V. Mehrmann, eds., acatech diskutiert, acatech, Springer, Berlin, Heidelberg, 2008, pp. 279--299, (Chapter Published).

Articles in Refereed Journals

Articles in Refereed Journals

-

N. Ouanes, T. González Grandón, H. Heitsch, R. Henrion, Optimizing the economic dispatch of weakly-connected mini-grids under uncertainty using joint chance constraints, Annals of Operations Research, 344 (2025), pp. 499--531 (published online on 25.09.2024), DOI 10.1007/s10479-024-06287-9 .

Abstract

In this paper, we deal with a renewable-powered mini-grid, connected to an unreliable main grid, in a Joint Chance Constrained (JCC) programming setting. In several rural areas in Africa with low energy access rates, grid-connected mini-grid system operators contend with four different types of uncertainties: forecasting errors of solar power and load; frequency and outages duration from the main-grid. These uncertainties pose new challenges to the classical power system's operation tasks. Three alternatives to the JCC problem are presented. In particular, we present an Individual Chance Constraint (ICC), Expected-Value Model (EVM) and a so called regular model that ignores outages and forecasting uncertainties. The JCC model has the capability to guarantee a high probability of meeting the local demand throughout an outage event by keeping appropriate reserves for Diesel generation and battery discharge. In contrast, the easier to handle ICC model guarantees such probability only individually for different time steps, resulting in a much less robust dispatch. The even simpler EVM focuses solely on average values of random variables. We illustrate the four models through a comparison of outcomes attained from a real mini-grid in Lake Victoria, Tanzania. The results show the dispatch modifications for battery and Diesel reserve planning, with the JCC model providing the most robust results, albeit with a small increase in costs. -

J.I. Asperheim, P. Das, B. Grande, D. Hömberg, Th. Petzold, Numerical simulation of high-frequency induction welding in longitudinal welded tubes, Journal of Mathematics in Industry, 14 (2024), pp. 10/1- -10/21, DOI 10.1186/s13362-024-00147-8 .

Abstract

In the present paper the high-frequency induction (HFI) welding process is studied numerically. The mathematical model comprises a harmonic vector potential formulation of the Maxwell equations and a quasi-static, convection dominated heat equation coupled through the joule heat term and nonlinear constitutive relations. Its main novelties are twofold: A new analytic approach permits to compute a spatially varying feed velocity depending on the angle of the Vee-opening and additional spring-back effects. Moreover, a numerical stabilization approach for the finite element discretization allows to consider realistic weld-line speeds and thus a fairly comprehensive three-dimensional simulation of the tube welding process. -

G. Padula, F. Romor, G. Stabile, G. Rozza, Generative models for the deformation of industrial shapes with linear geometric constraints: Model order and parameter space reductions, Computer Methods in Applied Mechanics and Engineering, 423 (2024), pp. 116823/1--116823/36, DOI 10.1016/j.cma.2024.116823 .

-

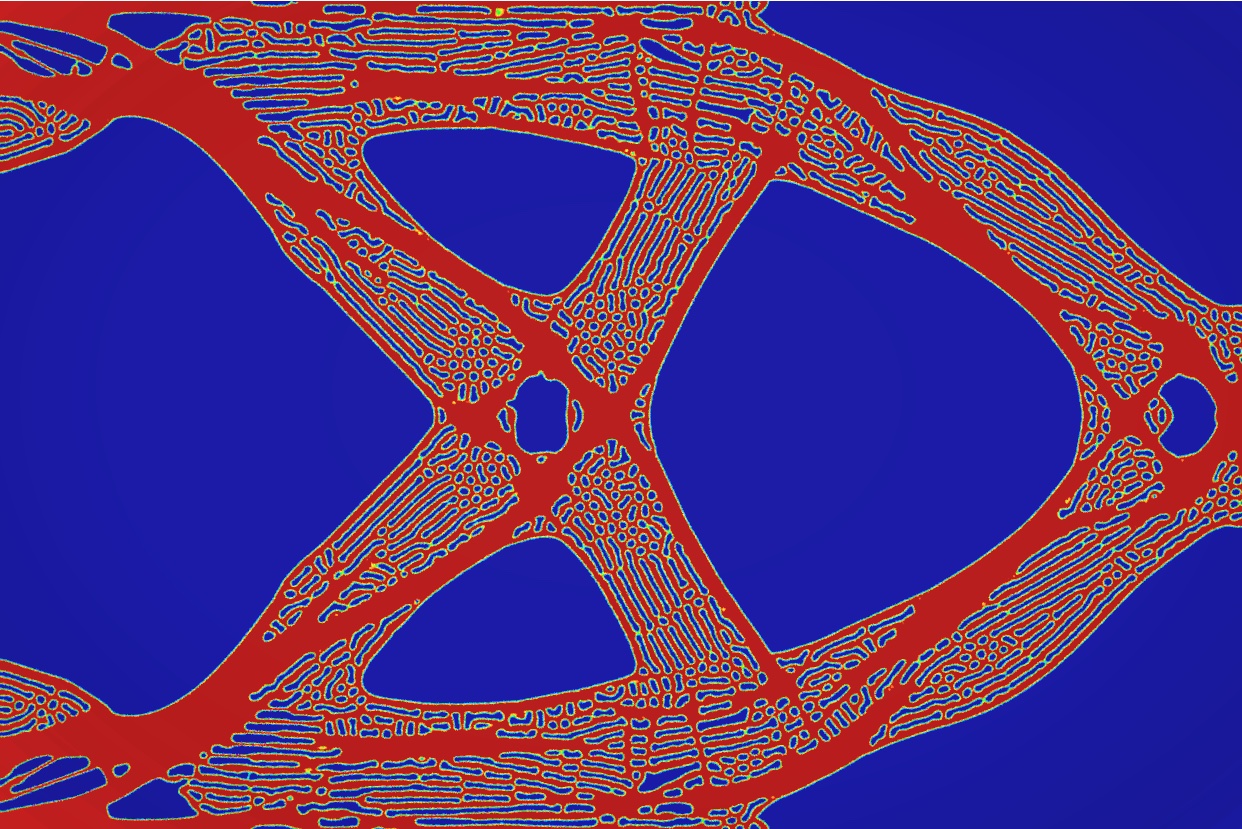

M. Ebeling-Rump, D. Hömberg, R. Lasarzik, On a two-scale phasefield model for topology optimization, Discrete and Continuous Dynamical Systems -- Series S, 17 (2024), pp. 326--361 (published online on 26.11.2023), DOI 10.3934/dcdss.2023206 .

Abstract

In this article, we consider a gradient flow stemming from a problem in two-scale topology optimization. We use the phase-field method, where a Ginzburg--Landau term with obstacle potential is added to the cost functional, which contains the usual compliance but also an additional contribution including a local volume constraint in a penalty term. The minimization of such an energy by its gradient-flow is analyzed in this paper. We use an regularization and discretization of the associated state-variable to show the existence of weak solutions to the considered system. -

D. Hömberg, R. Lasarzik, L. Plato, On the existence of generalized solutions to a spatio-temporal predator-prey system with prey-taxis, Journal of Evolution Equations, 23 (2023), pp. 20/1--20/44, DOI 10.1007/s00028-023-00871-5 .

Abstract

In this paper we consider a pair of coupled non-linear partial differential equations describing the interaction of a predator-prey pair. We introduce a concept of generalized solutions and show the existence of such solutions in all space dimension with the aid of a regularizing term, that is motivated by overcrowding phenomena. Additionally, we prove the weak-strong uniqueness of these generalized solutions and the existence of strong solutions at least locally-in-time for space dimension two and three. -

D.G. Gahururu, M. Hintermüller, Th.M. Surowiec, Risk-neutral PDE-constrained generalized Nash equilibrium problems, Mathematical Programming. A Publication of the Mathematical Programming Society, 198 (2023), pp. 1287--1337 (published online on 29.03.2022), DOI 10.1007/s10107-022-01800-z .

-

K. El Karfi, R. Henrion, D. Mentagui, An agricultural investment problem subject to probabilistic constraints, Computational Management Science, 19 (2022), pp. 683--701, DOI 10.1007/s10287-022-00431-1 .

-

M. Ebeling-Rump, D. Hömberg, R. Lasarzik, Two-scale topology optimization with heterogeneous mesostructures based on a local volume constraint, Computers & Mathematics with Applications. An International Journal, 126 (2022), pp. 100--114, DOI 10.1016/j.camwa.2022.09.004 .

Abstract

A new approach to produce optimal porous mesostructures and at the same time optimizing the macro structure subject to a compliance cost functional is presented. It is based on a phase-field formulation of topology optimization and uses a local volume constraint (LVC). The main novelty is that the radius of the LVC may depend both on space and a local stress measure. This allows for creating optimal topologies with heterogeneous mesostructures enforcing any desired spatial grading and accommodating stress concentrations by stress dependent pore size. The resulting optimal control problem is analysed mathematically, numerical results show its versatility in creating optimal macroscopic designs with tailored mesostructures. -

E. Vorontsova, A. Gasnikov, P. Dvurechensky, A. Ivanova, D. Pasechnyuk, Numerical methods for the resource allocation problem in a computer network, Computational Mathematics and Mathematical Physics, 61 (2021), pp. 297--328, DOI 10.1134/S0965542521020135 .

-

I. Shibaev, P. Dvurechensky, A. Gasnikov, Zeroth-order methods for noisy Hölder-gradient functions, Optimization Letters, published online in April 2021, DOI 10.1007/s11590-021-01742-z .

-

M.J. Arenas Jaén, D. Hömberg, R. Lasarzik, P. Mikkonen, Th. Petzold, Modelling and simulation of flame cutting for steel plates with solid phases and melting, Journal of Mathematics in Industry, 10 (2020), pp. 18/1--18/16, DOI 10.1186/s13362-020-00086-0 .

Abstract

The goal of this work is to describe in detail a quasi-stationary state model which can be used to deeply understand the distribution of the heat in a steel plate and the changes in the solid phases of the steel and into liquid phase during the flame cutting process. We use a 3D-model similar to previous works from Thiebaud [1] and expand it to consider phases changes, in particular, austenite formation and melting of material. Experimental data is used to validate the model and study its capabilities. Parameters defining the shape of the volumetric heat source and the power density are calibrated to achieve good agreement with temperature measurements. Similarities and differences with other models from literature are discussed. -

J.I. Asperheim, P. Das, B. Grande, D. Hömberg, Th. Petzold, Three-dimensional numerical study of heat affected zone in induction welding of tubes, COMPEL. The International Journal for Computation and Mathematics in Electrical and Electronic Engineering. Emerald, Bradford, West Yorkshire. English, English abstracts., 39 (2020), pp. 213--219, DOI 10.1108/COMPEL-06-2019-0238 .

-

P. Nestler, N. Schlömer, O. Klein, J. Sprekels, F. Tröltzsch, Optimal control of semiconductor melts by traveling magnetic fields, Vietnam Journal of Mathematics, 47 (2019), pp. 793--812, DOI 10.1007/s10013-019-00355-5 .

Abstract

In this paper, the optimal control of traveling magnetic fields in a process of crystal growth from the melt of semiconductor materials is considered. As controls, the phase shifts of the voltage in the coils of a heater-magnet module are employed to generate Lorentz forces for stirring the crystal melt in an optimal way. By the use of a new industrial heater-magnet module, the Lorentz forces have a stronger impact on the melt than in earlier technologies. It is known from experiments that during the growth process temperature oscillations with respect to time occur in the neighborhood of the solid-liquid interface. These oscillations may strongly influence the quality of the growing single crystal. As it seems to be impossible to suppress them completely, the main goal of optimization has to be less ambitious, namely, one tries to achieve oscillations that have a small amplitude and a frequency which is sufficiently high such that the solid-liquid interface does not have enough time to react to the oscillations. In our approach, we control the oscillations at a finite number of selected points in the neighborhood of the solidification front. The system dynamics is modeled by a coupled system of partial differential equations that account for instationary heat condution, turbulent melt flow, and magnetic field. We report on numerical methods for solving this system and for the optimization of the whole process. Different objective functionals are tested to reach the goal of optimization. -

D. Hömberg, K. Krumbiegel, N. Togobytska, Optimal control of multiphase steel production, Journal of Mathematics in Industry, 9 (2019), pp. 1--32, DOI 10.1186/s13362-019-0063-x .

Abstract

An optimal control problem for the production of multiphase steel is investigated, where the state equations are a semilinear heat equation and an ordinary differential equation, which describes the evolution of the ferrite phase fraction. The optimal control problem is analyzed and the first-order necessary and second-order sufficient optimality conditions are derived. For the numerical solution of the control problem reduced sequential quadratic programming (rSQP) method with a primal-dual active set strategy (PDAS) was applied. The numerical results were presented for the optimal control of a cooling line for production of hot rolled Mo-Mn dual phase steel. -

N. Alia, V. John, S. Ollila, Re-visiting the single-phase flow model for liquid steel ladle stirred by gas, Applied Mathematical Modelling. Simulation and Computation for Engineering and Environmental Systems. Elsevier Science Inc., New York, NY. English, English abstracts., 67 (2019), pp. 549--556 (published online on 21.11.2018), DOI 10.1016/j.apm.2018.11.005 .

-

L. Adam, M. Hintermüller, Th.M. Surowiec, A PDE-constrained optimization approach for topology optimization of strained photonic devices, Annali di Matematica Pura ed Applicata. Serie Quarta. Fondazione Annali di Matematica Pura ed Applicata, c/o Dipartimento di Matematica ``U. Dini'', Firenze; Springer-Verlag, Heidelberg. English, French, German, Italian, English abstracts., 19 (2018), pp. 521--557, DOI 10.1007/s11081-018-9394-5 .

Abstract

Recent studies have demonstrated the potential of using tensile-strained, doped Germanium as a means of developing an integrated light source for (amongst other things) future microprocessors. In this work, a multi-material phase-field approach to determine the optimal material configuration within a so-called Germanium-on-Silicon microbridge is considered. Here, an “optimal" configuration is one in which the strain in a predetermined minimal optical cavity within the Germanium is maximized according to an appropriately chosen objective functional. Due to manufacturing requirements, the emphasis here is on the cross-section of the device; i.e. a socalled aperture design. Here, the optimization is modeled as a non-linear optimization problem with partial differential equation (PDE) and manufacturing constraints. The resulting problem is analyzed and solved numerically. The theory portion includes a proof of existence of an optimal topology, differential sensitivity analysis of the displacement with respect to the topology, and the derivation of first and second-order optimality conditions. For the numerical experiments, an array of first and second-order solution algorithms in function-space are adapted to the current setting, tested, and compared. The numerical examples yield designs for which a significant increase in strain (as compared to an intuitive empirical design) is observed. -

K. Sturm, M. Hintermüller, D. Hömberg, Distortion compensation as a shape optimisation problem for a sharp interface model, Computational Optimization and Applications. An International Journal, 64 (2016), pp. 557--588.

Abstract

We study a mechanical equilibrium problem for a material consisting of two components with different densities, which allows to change the outer shape by changing the interface between the subdomains. We formulate the shape design problem of compensating unwanted workpiece changes by controlling the interface, employ regularity results for transmission problems for a rigorous derivation of optimality conditions based on the speed method, and conclude with some numerical results based on a spline approximation of the interface. -

D. Hömberg, Q. Liu, J. Montalvo-Urquizo, D. Nadolski, Th. Petzold, A. Schmidt, A. Schulz, Simulation of multi-frequency-induction-hardening including phase transitions and mechanical effects, Finite Elements in Analysis and Design, 121 (2016), pp. 86--100.

Abstract

Induction hardening is a well known method for the heat treatment of steel components. With the concept of multi-frequency hardening, where currents with two different frequency components are provided on a single inductor coil, it is possible to optimize the hardening zone to follow a given contour, e.g. of a gear. In this article, we consider the simulation of multi-frequency induction hardening in 3D. The equations to solve are the vector potential formulation of Maxwell's equations describing the electromagnetic fields, the balance of momentum to determine internal stresses and deformations arising from thermoelasticity and transformation induced plasticity, a rate law to determine the distribution of different phases and the heat equation to determine the temperature distribution in the workpiece. The equations are solved using adaptive finite element methods. The simulation results are compared to experiments for discs and for gears. A very good agreement for the hardening profile and the temperature is observed. It is also possible to predict the distribution of residual stresses after the heat treatment. -

TH. Petzold, D. Hömberg, D. Nadolski, A. Schulz, H. Stiele, Adaptive Finite-Elemente-Simulation des Mehrfrequenz-Induktionshärtens, HTM Journal for Heat Treatment and Materials, 70 (2015), pp. 33--39.

-

D. Hömberg, Th. Petzold, E. Rocca, Analysis and simulations of multifrequency induction hardening, Nonlinear Analysis. Real World Applications. An International Multidisciplinary Journal, 22 (2015), pp. 84--97.

Abstract

We study a model for induction hardening of steel. The related differential system consists of a time domain vector potential formulation of the Maxwell's equations coupled with an internal energy balance and an ODE for the volume fraction of austenite, the high temperature phase in steel. We first solve the initial boundary value problem associated by means of a Schauder fixed point argument coupled with suitable a-priori estimates and regularity results. Moreover, we prove a stability estimate entailing, in particular, uniqueness of solutions for our Cauchy problem. We conclude with some finite element simulations for the coupled system. -

W. Bleck, D. Hömberg, U. Prahl, P. Suwanpinij, N. Togobytska, Optimal control of a cooling line for production of hot rolled dual phase steel, Steel Research International, 85 (2014), pp. 1328--1333.

Abstract

In this article, the optimal control of a cooling line for production of dual phase steel in a hot rolling process is discussed. In order to achieve a desired dual phase steel microstructure an optimal cooling strategy has to be found. The cooling strategy should be such that a desired final distribution of ferrite in the steel slab is reached most accurately. This problem has been solved by means of mathematical control theory. The results of the optimal control of the cooling line have been verified in hot rolling experiments at the pilot hot rolling mill at the Institute for Metal Forming (IMF), TU Bergakademie Freiberg. -

A. Fügenschuh, B. Geissler, Ch. Hayn, R. Henrion, B. Hiller, J. Humpola, Th. Koch ET AL., Mathematical optimization for challenging network planning problems in unbundled liberalized gas markets, Energy Systems, 5 (2014), pp. 449--473.

-

D. Hömberg, S. Lu, K. Sakamoto, M. Yamamoto, Parameter identification in non-isothermal nucleation and growth processes, Inverse Problems. An International Journal on the Theory and Practice of Inverse Problems, Inverse Methods and Computerized Inversion of Data, 30 (2014), pp. 035003/1--035003/24.

Abstract

We study non-isothermal nucleation and growth phase transformations, which are described by a generalized Avrami model for the phase transition coupled with an energy balance to account for recalescence effects. The main novelty of our work is the identification of temperature dependent nucleation rates. We prove that such rates can be uniquely identified from measurements in a subdomain and apply an optimal control approach to develop a numerical strategy for its computation. -

K. Chełminski, D. Hömberg, O. Rott, On a thermomechanical milling model, Nonlinear Analysis. Real World Applications. An International Multidisciplinary Journal, 12 (2011), pp. 615--632.

Abstract

This paper deals with a new mathematical model to characterize the interaction between machine and workpiece in a milling process. The model consists of a harmonic oscillator equation for the dynamics of the cutter and a linear thermoelastic workpiece model. The coupling through the cutting force adds delay terms and further nonlinear effects. After a short derivation of the governing equations it is shown that the complete system admits a unique weak solution. A numerical solution strategy is outlined and complemented by numerical simulations of stable and unstable cutting conditions. -

A. Fasano, D. Hömberg, D. Naumov, On a mathematical model for laser-induced thermotherapy, Applied Mathematical Modelling. Simulation and Computation for Engineering and Environmental Systems. Elsevier Science Inc., New York, NY. English, English abstracts., 34 (2010), pp. 3831--3840.

Abstract

We study a mathematical model for laser-induced thermotherapy, a minimally invasive cancer treatment. The model consists of a diffusion approximation of the radiation transport equation coupled to a bio-heat equation and a model to describe the evolution of the coagulated zone. Special emphasis is laid on a refined model of the applicator device, accounting for the effect of coolant flow inside. Comparisons between experiment and simulations show that the model is able to predict the experimentally achieved temperatures reasonably well. -

D. Hömberg, Ch. Meyer, J. Rehberg, W. Ring, Optimal control for the thermistor problem, SIAM Journal on Control and Optimization, 48 (2010), pp. 3449--3481.

Abstract

This paper is concerned with the state-constrained optimal control of the two-dimensional thermistor problem, a quasi-linear coupled system of a parabolic and elliptic PDE with mixed boundary conditions. This system models the heating of a conducting material by means of direct current. Existence, uniqueness and continuity for the state system are derived by employing maximal elliptic and parabolic regularity. By similar arguments the linearized state system is discussed, while the adjoint system involving measures is investigated using a duality argument. These results allow to derive first-order necessary conditions for the optimal control problem. -

A. Fasano, D. Hömberg, L. Panizzi, A mathematical model for case hardening of steel, Mathematical Models & Methods in Applied Sciences, 19 (2009), pp. 2101--2126.

Abstract

A mathematical model for the case hardening of steel is presented. Carbon is dissolved in the surface layer of a low-carbon steel part at a temperature sufficient to render the steel austenitic, followed by quenching to form a martensitic microstructure. The model consists of a nonlinear evolution equation for the temperature, coupled with a nonlinear evolution equation for the carbon concentration, both coupled with two ordinary differential equations to describe the evolution of phase fractions. We investigate questions of existence and uniqueness of a solution and finally present some numerical simulations. -

D. Hömberg, D. Kern, The heat treatment of steel --- A mathematical control problem, Materialwissenschaft und Werkstofftechnik, 40 (2009), pp. 438--442.

Abstract

The goal of this paper is to show how the heat treatment of steel can be modelled in terms of a mathematical optimal control problem. The approach is applied to laser surface hardening and the cooling of a steel slab including mechanical effects. Finally, it is shown how the results can be utilized in industrial practice by a coupling with machine-based control. -

D. Hömberg, N. Togobytska, M. Yamamoto, On the evaluation of dilatometer experiments, Applicable Analysis. An International Journal, 88 (2009), pp. 669--681.

Abstract

The goal of this paper is a mathematical investigation of dilatometer experiments to measure the kinetics of solid-solid phase transitions in steel upon cooling from the high temperature phase. Usually, the data are only used for measuring the start and end temperature of the phase transition. In the case of several coexisting product phases, lavish microscopic investigations have to be performed to obtain the resulting fractions of the different phases. In contrast, we show that the complete phase transition kinetics including the final phase fractions are uniquely determined by the dilatometer data and present some numerical identification results. -

K. Chełminski, D. Hömberg, D. Kern, On a thermomechanical model of phase transitions in steel, Advances in Mathematical Sciences and Applications, 18 (2008), pp. 119--140.

-

P. Suwanpinij, N. Togobytska, Ch. Keul, W. Weiss, U. Prahl, D. Hömberg, W. Bleck, Phase transformation modeling and parameter identification from dilatometric investigations, Steel Research International, 79 (2008), pp. 793--799.

Abstract

The goal of this paper is to propose a new approach towards the evaluation of dilatometric results, which are often employed to analyse the phase transformation kinetics in steel, especially in terms of continuous cooling transformation (CCT) diagram. A simple task of dilatometry is deriving the start and end temperatures of the phase transformation. It can yield phase transformation kinetics provided that plenty metallographic investigations are performed, whose analysis is complicated especially in case of several coexisting product phases. The new method is based on the numerical solution of a thermomechanical identification problem. It is expected that the phase transformation kinetics can be derived by this approach with less metallographic tasks. The first results are remarkably promising although further investigations are required for the numerical simulations. -

H. Alder, D. Hömberg, W. Weiss, Simulationsbasierte Regelung der Laserhärtung von Stahl, HTM Zeitschrift für Werkstoffe. Wärmebehandlung. Fertigung, 61 (2006), pp. 103--108.

-

D. Hömberg, W. Weiss, PID control of laser surface hardening of steel, IEEE Transactions on Control Systems Technology, 14 (2006), pp. 896--904.

-

D. Hömberg, A mathematical model for induction hardening including mechanical effects, Nonlinear Analysis. Real World Applications. An International Multidisciplinary Journal, 5 (2004), pp. 55--90.

-

D. Hömberg, J. Sokolowski, Optimal shape design of inductor coils for induction hardening, SIAM Journal on Control and Optimization, 42 (2003), pp. 1087--1117.

-

D. Hömberg, S. Volkwein, Control of laser surface hardening by a reduced-order approach using proper orthogonal decomposition, Mathematical and Computer Modelling, 38 (2003), pp. 1003-1028.

Contributions to Collected Editions

Contributions to Collected Editions

-

G. Thiele, Th. Johanni, D. Sommer, M. Eigel, J. Krüger, OptTopo: Automated set-point optimization for coupled systems using topology information, in: 2022 8th International Conference on Control, Decision and Information Technologies (CoDIT), IEEE, 2022, pp. 224--229, DOI 10.1109/CoDIT55151.2022.9803985 .

-

G. Thiele, A. Fey, D. Sommer, J. Krüger, System identification of a hysteresis-controlled pump system using SINDy, in: 2020 24th International Conference on System Theory, Control and Computing (ICSTCC), IEEE, 2020, pp. 457--464, DOI 10.1109/ICSTCC50638.2020.9259776 .

Abstract

Hysteresis-controlled devices are widely used in industrial applications. For example, cooling devices usually contain a two-point controller, resulting in a nonlinear hybrid system with two discrete states. Dynamic models of systems are essential for optimizing such industrial supply technology. However, conventional system identification approaches can hardly handle hysteresis-controlled devices. Thus, the new identification method Sparse Identification of Nonlinear Dynamics (SINDy) is extended to consider hybrid systems. SINDy composes models from basis functions out of a customized library in a data-driven manner. For modeling systems that behave dependent on their own past as in the case of natural hysteresis, Ferenc Preisach introduced the relay hysteron as an elementary mathematical description. In this new method (SINDyHybrid), tailored basis functions in form of relay hysterons are added to the library which is used by SINDy. Experiments with a hysteresis controlled water basin show that this approach correctly identifies state transitions of hybrid systems and also succeeds in modeling the dynamics of the discrete system states. A novel proximity hysteron achieves the robustness of this method. The impacts of the sampling rate and the signal noise ratio of the measurement data are examined accordingly. -

M. Hintermüller, N. Strogies, On the consistency of Runge--Kutta methods up to order three applied to the optimal control of scalar conservation laws, in: Numerical Analysis and Optimization, M. Al-Baali, L. Grandinetti, A. Purnama, eds., 235 of Springer Proceedings in Mathematics & Statistics, Springer Nature Switzerland AG, Cham, 2019, pp. 119--154.

Abstract

Higher-order Runge-Kutta (RK) time discretization methods for the optimal control of scalar conservation laws are analyzed and numerically tested. The hyperbolic nature of the state system introduces specific requirements on discretization schemes such that the discrete adjoint states associated with the control problem converge as well. Moreover, conditions on the RK-coefficients are derived that coincide with those characterizing strong stability preserving Runge-Kutta methods. As a consequence, the optimal order for the adjoint state is limited, e.g., to two even in the case where the conservation law is discretized by a third-order method. Finally, numerical tests for controlling Burgers equation validate the theoretical results. -

M. Hintermüller, T. Keil, Some recent developments in optimal control of multiphase flows, in: Shape Optimization, Homogenization and Optimal Control. DFG-AIMS Workshop held at the AIMS Center Senegal, March 13--16, 2017, V. Schulz, D. Seck, eds., 169 of International Series of Numerical Mathematics, Birkhäuser, Springer Nature Switzerland AG, Cham, 2018, pp. 113--142, DOI 10.1007/978-3-319-90469-6_7 .

-

L. Capone, Th. Petzold, D. Hömberg, D. Ivanov, A novel integrated tool for parametric geometry generation and simulation for induction hardening of gears, in: Heat Treat 2017: Proceedings of the 29th AMS Heat Treating Society Conference, October 24--26, 2017, Columbus, Ohio, USA, ASM International, Materials Park, Ohio, 2017, pp. 234--242.

-

P. Das, J.I. Asperheim, B. Grande, Th. Petzold, D. Hömberg, Simulation of temperature profile in longitudinal welded tubes during high-frequency induction (HFI) welding, in: Heat Treat 2017: Proceedings of the 29th AMS Heat Treating Society Conference, October 24--26, 2017, Columbus, Ohio, USA, ASM International, Materials Park, Ohio, 2017, pp. 534--538.

-

Q. Liu, Th. Petzold, D. Nadolski, R. Pulch, Simulation of thermomechanical behavior subjected to induction hardening, in: Scientific Computing in Electrical Engineering, SCEE 2014, Wuppertal, Germany, July 2014, A. Bartel, M. Clemens, M. Günther, E.J.W. TER Maten, eds., 23 of Mathematics in Industry, Springer International Publishing Switzerland, Cham, 2016, pp. 133--142.

-

CH. Landry, M. Gerdts, R. Henrion, D. Hömberg, W. Welz, Collision-free path planning of welding robots, in: Progress in Industrial Mathematics at ECMI 2012, M. Fontes, M. Günther, N. Marheineke, eds., 19 of Mathematics in Industry, Springer, Cham et al., 2014, pp. 251--256.

-

T. Bosse, R. Henrion, D. Hömberg, Ch. Landry, H. Leövey ET AL., C2 -- Nonlinear programming with applications to production processes, in: MATHEON -- Mathematics for Key Technologies, M. Grötschel, D. Hömberg, J. Sprekels, V. Mehrmann ET AL., eds., 1 of EMS Series in Industrial and Applied Mathematics, European Mathematical Society Publishing House, Zurich, 2014, pp. 171--187.

-

C. Carstensen, M. Hintermüller, D. Hömberg, F. Tröltzsch, C -- Production, in: MATHEON -- Mathematics for Key Technologies, M. Grötschel, D. Hömberg, J. Sprekels, V. Mehrmann ET AL., eds., 1 of EMS Series in Industrial and Applied Mathematics, European Mathematical Society Publishing House, Zurich, 2014, pp. 151--153.

-

M. Hintermüller, D. Hömberg, O. Klein, J. Sprekels, F. Tröltzsch, C4 -- PDE-constrained optimization with industrial applications, in: MATHEON -- Mathematics for Key Technologies, M. Grötschel, D. Hömberg, J. Sprekels, V. Mehrmann ET AL., eds., 1 of EMS Series in Industrial and Applied Mathematics, European Mathematical Society Publishing House, Zurich, 2014, pp. 207--222.

-

D. Hömberg, E. Rocca, Th. Petzold, Multi-frequency induction hardening -- A challenge for industrial mathematics, in: The Impact of Applications on Mathematics -- Proceedings of the Forum of Mathematics for Industry 2013, M. Wakayama, ed., 1 of Mathematics for Industry, Springer, Tokyo et al., 2014, pp. 257--264.

-

D. Hömberg, Th. Petzold, Modelling and simulation of multi-frequency induction hardening of steel parts, in: Proceedings of the International Scientific Colloquium ``Modelling for Electromagnetic Processing'', MEP 2014, E. Baake, B. Nacke, eds., Leibniz University of Hannover, 2014, pp. 245--250.

-

D. Hömberg, S. Lu, K. Sakamoto, M. Yamamoto, Nucleation rate identification in binary phase transition, in: The Impact of Applications on Mathematics -- Proceedings of the Forum of Mathematics for Industry 2013, M. Wakayama, ed., 1 of Mathematics for Industry, Springer, Tokyo et al., 2014, pp. 227--243.

-

L. Panizzi, A. Fasano, D. Hömberg, Modeling, analysis and simulations of case hardening of steel, in: Progress in Industrial Mathematics at ECMI 2008, A. Fitt, J. Norbury, H. Ockendon, E. Wilson, eds., 15 of Mathematics in Industry, Springer, Berlin et al., 2010, pp. 965--970.

-

P. Rasper, O. Rott, D. Hömberg, E. Uhlmann, Analysis of uncertainties in the stability prediction for milling processes, in: Conference Proceedings, CIRP 2nd International Conference ``Process Machine Interactions'', June 10--11, 2010, Vancouver (CD), Y. Altintas, B. Denkena, Ch. Brecher, eds., 2010, pp. M18/1--M18/12.

-

D. Hömberg, O. Rott, Modeling, analysis and stability of milling processes including workpiece effects, in: Progress in Industrial Mathematics at ECMI 2008, A. Fitt, J. Norbury, H. Ockendon, E. Wilson, eds., 15 of Mathematics in Industry, Springer, Berlin et al., 2010, pp. 493--498.

-

O. Rott, P. Rasper, D. Hömberg, E. Uhlmann, A milling model with thermal effects including the dynamics of machine and work piece, B. Denkena, ed., Proceedings, 1st International Conference on Process Machine Interactions, Hannover, September 3--4, 2008, PZH Produktionstechnisches Zentrum GmbH, Garbsen, 2008, pp. 369--378.

Abstract

This paper deals with the development of a new mathematical model that characterizes the structure-process interaction for a complex milling system. The structure is divided into a work piece and a machine part, which are represented by different models. While the machine dynamics is characterized by a standard multi-body system, the work piece is described as a linear thermo-elastic continuum. The coupling of both parts is carried out by an empirical process model permitting an estimate of heat and coupling forces occurring during milling. This work reports the derivation of the governing equations emphasizing the coupling and summarizes the numerical algorithms being applied to solve the coupled equation system. The results of numerical simulations that show the dynamics of the complex thermo-mechanical system are presented at the end. -

D. Hömberg, D. Kern, The heat treatment of steel --- A mathematical control problem, in: Proceedings of the 2nd International Conference on Distortion Engineering -- IDE 2008, 17--19 September 2008, Bremen, Germany, H.-W. Zoch, Th. Lübben, eds., IWT, Bremen, 2008, pp. 201--209.

-

CH. Meyer, D. Hömberg, J. Rehberg, W. Ring, Optimal control of the thermistor problem, in: Optimal Control of Coupled Systems of PDE, Workshop, March 2--8, 2008, 5 of Oberwolfach Reports, Mathematisches Forschungsinstitut Oberwolfach, 2008, pp. 624-626.

-

D. Hömberg, D. Kern, W. Weiss, Die Wärmebehandlung von Stahl --- ein Optimierungsproblem, in: Distortion Engineering -- Verzugsbeherrschung in der Fertigung III --, 3 of Sonderforschungsbereich 570, Universität Bremen, Kolloquium, 2006, pp. 39--55.

-

M. Anthonissen, D. Hömberg, W. Weiss, Real-time control of surface remelting, in: Progress in Industrial Mathematics at ECMI 2004, A. Di Bucchianico, R.M.M. Mattheij, M.A. Peletier, eds., 8 of Mathematics in Industry, Springer, 2005, pp. 356--360.

-

D. Hömberg, S. Volkwein, W. Weiss, Optimal control strategies for the surface hardening of steel, in: Proceedings of the 2nd International Conference on Thermal Process Modelling and Computer Simulation, S. Denis, P. Archambault, J.-M. Bergheau, R. Fortunier, eds., 120 of J. Physique IV, EDP Sciences, 2004, pp. 325--335.

Preprints, Reports, Technical Reports

Preprints, Reports, Technical Reports

-

M.J. Arenas, D. Hömberg, R. Lasarzik, Optimal beam forming for laser materials processing, Preprint no. 3080, WIAS, Berlin, 2023, DOI 10.20347/WIAS.PREPRINT.3080 .

Abstract, PDF (2441 kByte)

We investigate an optimal control problem related to laser material treatments such as welding, remelting, hardening, or the 3D printing of metal components. The mathematical model leads to the investigation of a quasilinear elliptic state system with additional non-monotone lower-oder terms. We analyze the state system, derive first order optimality conditions and show first results for beam shaping. -

D. Hömberg, O. Rott, K. Sturm, Discretisation and error analysis for a mathematical model of milling processes, Preprint no. 2364, WIAS, Berlin, 2016, DOI 10.20347/WIAS.PREPRINT.2364 .

Abstract, PDF (565 kByte)

We investigate a mathematical model for milling where the cutting tool dynamics is considered together with an elastic workpiece model. Both are coupled by the cutting forces consisting of two dynamic components representing vibrations of the tool and of the workpiece, respectively, at the present and previous tooth periods. We develop a numerical solution algorithm and derive error estimates both for the semi-discrete and the fully discrete numerical scheme. Numerical computations in the last section support the analytically derived error estimates. -

M. Graf, D. Hömberg, R. Kawalla, N. Togobytska, W. Weiss, Identification, simulation and optimal control of heat transfer in cooling line of hot strip rolling mill, Preprint no. 1769, WIAS, Berlin, 2013, DOI 10.20347/WIAS.PREPRINT.1769 .

Abstract, PDF (10 MByte)

The numerical simulation of mechanical properties of hot-rolled products has a major significance for material characterisation as well as material development. The basis for these is the knowledge about the material-specific phase transformations in combination with the initial microstructure from the deformation steps before entering into the cooling line. Additionally, the technological conditions in the run-out table (ROT) are essentially for transformation kinetics. In order to simulate these processes, the plant-specific heat transfer coefficient must be measured. Therefore, steel samples with thermocouples inside are transported with defined velocities through the cooling line of the continuous pilot plant at the Institute of Metal Forming in Freiberg. Furthermore, the material and its movement must be taken into account as characteristics of the ROT (e.g. amount and distribution of the cooling medium, the streaming situation in several segments, the nozzle geometry and, as a consequence, the water jet shape, and the impact pressure of the cooling medium on the surface of the rolled material) as influencing parameters. This paper describes the possibilities for determining and simulating the heat transfer in the cooling line with industrial conditions. Moreover, this paper discusses the optimal control of the cooling line to achieve the desired temperature and phase distribution on the run-out table. The resulting information contributes to new technology and material developments at the pilot plant, as well as for the transfer of results into the industry. -

O. Rott, E. Jarlebring, An iterative method for the multipliers of periodic delay-differential equations and the analysis of a PDE milling model, Preprint no. 1470, WIAS, Berlin, 2009, DOI 10.20347/WIAS.PREPRINT.1470 .

Abstract, Postscript (670 kByte), PDF (189 kByte)

Locally convergent iterative schemes have turned out to be very useful in the analysis of the characteristic roots of delay-differential equations (DDEs) with constant coefficients. In this work we present a locally convergent iterative scheme for the characteristic multipliers of periodic-coefficient DDEs. The method is an adaption of an iterative method called residual inverse iteration. The possibility to use this method stems from an observation that the characteristic matrix can be expressed with the fundamental solution of a differential equation. We apply the method to a coupled milling model containing a partial and an ordinary differential equation. The conclusion of the numerical results is that the stability diagram of the coupled model differs significantly from the combined stability diagrams for each subsystem. -

D. Hömberg, A. Steinbrecher, T. Stykel, Optimal control of robot-guided laser material treatment, Preprint no. 1405, WIAS, Berlin, 2009, DOI 10.20347/WIAS.PREPRINT.1405 .

Abstract, Postscript (10 MByte), PDF (2216 kByte)

In this article we will consider the optimal control of robot guided laser material treatments, where the discrete multibody system model of a robot is coupled with a PDE model of the laser treatment. We will present and discuss several optimization approaches of such optimal control problems and its properties in view of a robust and suitable numerical solution. We will illustrate the approaches in an application to the surface hardening of steel. -

W. Dreyer, D. Hömberg, Th. Petzold, A model for the austenite-ferrite phase transition in steel including misfit stress, Preprint no. 1310, WIAS, Berlin, 2008, DOI 10.20347/WIAS.PREPRINT.1310 .

Abstract, Postscript (730 kByte), PDF (445 kByte)

We present a thermodynamically consistent model to describe the austenite-ferrite phase transition in steel. We consider the influence of the mechanical displacement field due to eigenstrains caused by volumetric expansion. The model equations are derived in a systematical framework. They are based on the conservation laws for mass and momentum and the second law of thermodynamics. By means of numerical computations for a simplified interface controlled model, we examine the influence of the mechanical contributions to the transformation kinetics and the equilibrium states.

Talks, Poster

Talks, Poster

-

M. Hintermüller, A PINN-based multi-complexity solver as a PDE-constrained optimization problem, The Third HKSIAM Biennial Conference, Department of Mathematics, The Chinese University of Hong Kong, China, July 8, 2025.

-

M. Hintermüller, QVIs: Semismooth Newton, optimal control, and uncertainties, RICAM Colloquium, Johann Radon Institute for Computational and Applied Mathematics (RICAM), Linz, Austria, June 27, 2024.

-

R. Henrion, Turnpike phenomenon in discrete-time optimal control with probabilistic constraint, 2nd Vienna Workshop on Computational Optimization, March 15 - 17, 2023, Universität Wien, Austria, March 15, 2023.

-

M. Hintermüller, A descent algorithm for the optimal control of ReLU neural network Informed PDEs based on approximate directional derivatives, FoCM 2023 -- Foundations of Computational Mathematics, Session II.2: ``Continuous Optimization'', June 12 - 21, 2023, Sorbonne University, Paris, France, June 15, 2023.

-

M. Hintermüller, Learning-informed and PINN-based multi scale PDE models in optimization, Conference on Deep Learning for Computational Physics, July 4 - 6, 2023, UCL -- London's Global University, UK, July 6, 2023.

-

M. Hintermüller, Optimal control of (quasi)variational inequalities: Stationarity, risk-aversion, and numerical solution, Workshop on Optimization, Equilibrium and Complementarity, August 16 - 19, 2023, The Hong Kong Polytechnic University, Department of Applied Mathematic, August 19, 2023.

-

M. Hintermüller, PDE-constrained optimization with non-smooth learning-informed structures, 10th International Congress on Industrial and Applied Mathematics (ICIAM 2023), Minisymposium 00711 ``Recent Advances in Optimal Control and Optimization'', August 20 - 25, 2023, Waseda University, Tokyo, Japan, August 21, 2023.

-

D. Hömberg, On two-scale topology optimization for AM, The Fourth International Conference on Simulation for Additive Manufacturing (Sim-AM 2023), IS14 ``Advanced Methods and Innovative Technologies for the Optimal Design of Structures and Materials II'', July 26 - 28, 2023, Galileo Science Congress Center Munich-Garching, Garching, July 27, 2023.

-

D. Hömberg, Phase-field based topology optimization, Norwegian Workshop on Mathematical Optimization, Nonlinear and Variational Analysis 2023, April 26 - 28, 2023, Norwegian University of Science and Technology, Trondheim, Norway, April 27, 2023.

-

D. Hömberg, Two-scale topology optimization -- A phase field approach, 22nd European Conference on Mathematics for Industry (ECMI2023), MS17 ``ECMI SIG: Mathematics for the Digital Factory'', June 26 - 30, 2023, Wrocław University of Science and Technology Congress Centre, Poland, June 26, 2023.

-

M. Hintermüller, A descent algorithm for the optimal control of ReLU neural network informed PDEs based on approximate directional derivatives (online talk), Workshop 2: Structured Optimization Models in High-Dimensional Data Analysis, December 12 - 16, 2022, National University of Singapore, Institute for Mathematical Sciences, December 15, 2022.

-

M. Hintermüller, Optimization subject to learning informed PDEs, International Conference on Continuous Optimization -- ICCOPT/MOPTA 2022, Cluster ``PDE-Constrained Optimization'', July 23 - 28, 2022, Lehigh University, Bethlehem, Pennsylvania, USA, July 27, 2022.

-

M. Hintermüller, Optimization with learning-informed differential equation constraints (online talk), Workshop on Control Problems (Online Event), October 17 - 20, 2022, Technische Universität Dortmund, October 17, 2022.

-

M. Hintermüller, PDE-constrained optimization with learning-informed structures (online talk), Optimization in Oslo (OiO) Seminar, Simula Research Laboratory, Norway, December 7, 2022.

-

P. Farrell, Modelling and simulation of the lateral photovoltage scanning method (online talk), European Conference on Mathematics for Industry (ECMI2021), MSOEE: ``Mathematical Modeling of Charge Transport in Graphene and Low dimensional Structures'' (Online Event), April 13 - 15, 2021, Bergische Universität Wuppertal, April 13, 2021.

-

D. Sommer, Robust nonlinear model predictive control using tensor networks (online talk), European Conference on Mathematics for Industry (ECMI2021), MS23: ``Data-Driven Optimization'' (Online Event), April 13 - 15, 2021, Bergische Universität Wuppertal, April 14, 2021.

-

M. Hintermüller, Optimal control of quasi-variational inequalities (online talk), SIAM Conference on Optimization (OP21) (Online Event), Minisymposium MS93 ``Nonsmooth Problems and Methods in Large-scale Optimization'', July 20 - 23, 2021, July 23, 2021.

-

M. Hintermüller, Optimization with learning-informed differential equation constraints and its applications, Online Conference ``Industrial and Applied Mathematics'', January 11 - 15, 2021, The Hong Kong University of Science and Technology, Institute for Advanced Study, January 13, 2021.

-

M. Hintermüller, Optimization with learning-informed differential equation constraints and its applications (online talk), One World Optimization Seminar, Universität Wien, Fakultät für Mathematik, Austria, May 10, 2021.

-

M. Hintermüller, Semi-smooth Newton methods: Theory, numerical algorithms and applications I (online talk), International Forum on Frontiers of Intelligent Medical Image Analysis and Computing 2021 (Online Forum), Xidian University, Southeastern University, and Hong Kong Baptist University, China, July 19, 2021.

-

M. Hintermüller, Semi-smooth Newton methods: Theory, numerical algorithms and applications II (online talk), International Forum on Frontiers of Intelligent Medical Image Analysis and Computing 2021 (Online Forum), Xidian University, Southeastern University, and Hong Kong Baptist University, China, July 26, 2021.

-

D. Hömberg, Mathematics for steel production and manufacturing (online talk), Cardiff University, School of Mathematics, UK, March 2, 2021.

-

D. Hömberg, Modelling and simulation of high-frequency induction welding (online talk), European Conference on Mathematics for Industry (ECMI2021), MS08: ``Modelling, Simulation and Optimization in Electrical Engineering'' (Online Event), April 13 - 15, 2021, Bergische Universität Wuppertal, April 13, 2021.

-

H. Nguyen, A shape optimization problem for stationary Navier--Stokes flows in three-dimensional tubes, Model Order Reduction Summer School 2020 (MORSS 2020), September 7 - 10, 2020, École polytechnique fédérale de Lausanne (EPFL), Lausanne, Switzerland, September 7, 2020.

-

C. Löbhard, Space-time discretization for parabolic optimal control problems with state constraints, ICCOPT 2019 -- Sixth International Conference on Continuos Optimization, Session ``Optimal Control and Dynamical Systems (Part VI)'', August 5 - 8, 2019, Berlin, August 7, 2019.

-

M. Hintermüller, Lecture Series: Optimal control of nonsmooth structures, Thematic Programme ``Modern Maximal Monotone Operator Theory: From Nonsmooth Optimization to Differential Inclusions'', February 4 - 7, 2019, Erwin Schrödinger International Institute for Mathematics and Physics, Vienna, Austria.

-

M. Hintermüller, Optimal control of multiphase fluids and droplets, Polish Academy of Sciences, Systems Research Institute, Warsaw, Poland, December 3, 2019.

-

D. Hömberg, MSO for steel production and manufacturing, 9th International Congress on Industrial and Applied Mathematics (ICIAM), Minisymposium IM FT-4-2 1 ``Academia-Industry Case Studies from MI-NET and ECMI'', July 15 - 19, 2019, Valencia, Spain, July 15, 2019.

-

D. Hömberg, Mathematics for steel production and manufacturing, Conference ``Dynamics, Equations and Applications (DEA 2019)'', Session ``D442 Complex Systems in Material Science'', September 16 - 20, 2019, AGH University of Science and Technology, Kraków, Poland, September 17, 2019.

-

D. Hömberg, Mathematics for steel production and manufacturing, Sondierungsworkshop MPIE/WIAS ``Elektrochemie, Halbleiternanostrukturen und Metalle'', October 14 - 15, 2019, Max-Planck-Institut für Eisenforschung GmbH Düsseldorf, October 14, 2019.

-

D. Hömberg, Maths for digital factory, Polytechnic of Leiria, Center for Rapid and Sustainable Product Development, Marinha Grande, Portugal, October 10, 2019.

-

N. Alia, Modeling and optimization of a gas-stirred liquid flow for steelmaking processes, The 20th European Conference on Mathematics for Industry (ECMI), MS27: MSO for steel production and manufacturing, June 18 - 22, 2018, University Budapest, Institute of Mathematics at Eötvös Loránd, Hungary, June 19, 2018.

-

M. Hintermüller, Nonsmooth structures in PDE constrained optimization, Mathematisches Kolloquium, Universität Bielefeld, Fakultät für Mathematik, June 7, 2018.

-

M. Hintermüller, Recent advances in non-smooth and complementarity-based distributed parameter systems, 89th Annual Meeting of the International Association of Applied Mathematics and Mechanics (GAMM 2018), Session PP07 ``DFG Priority Program 1962'', March 19 - 23, 2018, Technische Universität München, March 20, 2018.

-

M. Hintermüller, Semismooth Newton methods in PDE constrained optimization, Advanced Training in Mathematics Schools ``New Directions in PDE Constrained Optimisation'', March 12 - 16, 2018, National Centre for Mathematics of IIT Bombay and TIFR, Mumbai, Bombay, India.

-

D. Hömberg, European collaboration in industrial and applied mathematics, Conference ``Mathematical Modelling in Metallurgical Industry'', September 17 - 18, 2018, Kristiansand, Norway, September 18, 2018.

-

D. Hömberg, European collaboration in industrial and applied mathematics, Salzburg Mathematics Colloquium, Universität Salzburg, Fachbereich Mathematik, Austria, May 17, 2018.

-

D. Hömberg, European collaboration in industrial and applied mathematics, Inderprastha Engineering College, Ghaziabad, India, January 5, 2018.

-

D. Hömberg, Knowledge exchange in mathematics -- The European perspective, 1st IMA Conference on Knowledge Exchange in the Mathematical Sciences, December 3 - 4, 2018, Aston University, Birmingham, UK, December 3, 2018.

-

D. Hömberg, Mathematical challenges in steel manufacturing, Second International Conference on Modern Mathematical Methods and High Performance Computing in Science and Technology (M3HPCST 2018), January 4 - 6, 2018, Inderprastha Engineering College (IPEC), Ghaziabad, India, January 4, 2018.

-

D. Hömberg, Maths for digital factory, University of Southern Denmark, The Maersk Mc-Kinney Moller Institute, Odense, Denmark, October 12, 2018.

-

D. Hömberg, Temporal homogenization of a nonlinear parabolic system, The 20th European Conference on Mathematics for Industry (ECMI 2018), Minisymposium 15 ``Electromagnetic Problems Arising in Industry: Modelling and Numerical Techniques'', June 18 - 22, 2018, Budapest, Hungary, June 18, 2018.

-

C. Löbhard, A function space based solution method with space-time adaptivity for parabolic optimal control problems with state constraints, PGMO Days 2017, November 13 - 14, 2017, EDF Lab Paris Saclay, France, November 14, 2017.

-

C. Löbhard, An ddaptive discontinuous Galerkin method for a parabolic optimal control problem with state constraints . . ., Workshop on Optimization of Infinite Dimensional Non-Smooth Distributed Parameter Systems, October 4 - 6, 2017, Darmstadt, October 4, 2017.

-

C. Löbhard, Space-time discretization of a parabolic optimal control problem with state constraints, 18th French-German-Italian Conference on Optimization, September 25 - 28, 2017, Paderborn, September 26, 2017.

-

R. Henrion, On M-stationary condition for a simple electricity spot market model, Workshop ``Variational Analysis and Applications for Modelling of Energy Exchange'', May 4 - 5, 2017, Université Perpignan, France, May 4, 2017.

-

M. Hintermüller, Adaptive finite element solvers for MPECs in function space, SIAM Conference on Optimization, Minisymposium MS122 ``Recent Trends in PDE-Constrained Optimization'', May 22 - 25, 2017, Vancouver, British Columbia, Canada, May 25, 2017.

-

M. Hintermüller, Nonsmooth structures in PDE constrained optimization, Optimization Seminar, Chinese Academy of Sciences, State Key Laboratory of Scientific and Engineering Computing, Beijing, China, June 6, 2017.

-

M. Hintermüller, Optimal control of multiphase fluids based on non smooth models, 14th International Conference on Free Boundary Problems: Theory and Applications, Theme Session 8 ``Optimization and Control of Interfaces'', July 9 - 14, 2017, Shanghai Jiao Tong University, China, July 10, 2017.

-

D. Hömberg, From dilatometer experiments to distortion compensation -- Optimal control problems related to solid-solid phase transitions, Norwegian University of Science and Technology, Department of Mathematical Sciences, Trondheim, Norway, November 3, 2017.

-

D. Hömberg, MSO for steel production and manufacturing, Workshop ``Future and Emerging Mathematical Technologies in Europe'', December 11 - 15, 2017, Lorentz Center, Leiden, Netherlands, December 11, 2017.

-

D. Hömberg, Mathematical aspects of multi-frequency induction heating, Universidade Técnica de Lisboa, Instituto Superior Técnico, Portugal, February 2, 2017.

-

D. Hömberg, On a robust phase field approach to topology optimization, Università degli Studi di Pavia, Dipartimento di Matematica, Italy, April 28, 2017.

-

TH. Petzold, The MIMESIS project -- An example for an interdisciplinary research project, Leibniz-Kolleg for Young Researchers: Chances and Challenges of Interdisciplinary Research, Thematic Workshop ``Models and Modelling'', November 9 - 11, 2016, Leibniz-Gemeinschaft, Berlin, November 9, 2016.

-

M.H. Farshbaf Shaker, Allen--Cahn MPECs, WIAS-PGMO Workshop on Nonsmooth and Stochastic Optimization with Applications to Energy Management, May 10 - 12, 2016, WIAS Berlin, May 11, 2016.

-

M. Hintermüller, Optimal control of multiphase fluids and droplets, Salzburg Mathematics Colloquium, Universität Salzburg, Fachbereich Mathematik, Austria, June 9, 2016.

-

M. Hintermüller, Recent trends in optimal control problems with nonsmooth structures, Computational Methods for Control of Infinite-dimensional Systems, March 14 - 18, 2016, Institute for Mathematics and its Applications, Minneapolis, USA, March 14, 2016.

-

D. Hömberg, Analysis and simulation of Joule heating problems, Mathematisches Kolloquium, Bergische Universität Wuppertal, Fachgruppe Mathematik und Informatik, June 21, 2016.

-

D. Hömberg, European Industrial Doctorates -- A funding opportunity for collaboration with industry, Math Meets Industry, September 22 - 23, 2016, Trondheim, Norway, September 22, 2016.

-

D. Hömberg, European collaboration in Industrial and Applied Mathematics, The 19th European Conference on Mathematics for Industry (ECMI 2016), Minisymposium 38 ``Maths in HORIZON 2020 and Beyond'', June 13 - 17, 2016, Universidade de Santiago de Compostela, Spain, June 15, 2016.

-

D. Hömberg, Math for steel production and manufacturing, MACSI10 -- Empowering Industrial Mathematical and Statistical Modelling for the Future, December 8 - 9, 2016, University of Limerick, Ireland, December 9, 2016.

-

D. Hömberg, Modelling and simulation of multi-frequency induction hardening, Fifth Chilean Workshop on Numerical Analysis of Partial Differential Equations (WONAPDE 2016), January 11 - 15, 2016, Universidad de Concepción, Chile, January 14, 2016.

-

D. Hömberg, Multifrequency induction hardening -- Modelling and simulation, Fraunhofer-Institut für Techno- und Wirtschaftsmathematik, Kaiserslautern, May 17, 2016.

-

D. Hömberg, Modelling, analysis and simulation of multifrequency induction hardening, XXIV Congress on Differential Equations and Applications (CEDYA)/XIV Congress on Applied Mathematics (CMA), June 8 - 12, 2015, Universidad de Cádiz, Spain, June 11, 2015.

-

D. Hömberg, Nucleation, growth, and grain size evolution in multiphase materials, INdAM Workshop ``Special Materials in Complex Systems -- SMaCS 2015'', May 18 - 22, 2015, Rome, Italy, May 21, 2015.

-

D. Hömberg, Optimal coefficient control for semilinear parabolic equations, Fudan University, School of Mathematical Sciences, Shanghai, China, March 10, 2015.

-

D. Hömberg, The digital factory -- A perspective for a closer cooperation between math and industry, Workshop ``Mathematics and Computer Science in Practice: Potential and Reality'', December 9 - 11, 2015, Prague, Czech Republic, December 9, 2015.

-

TH. Petzold, Adaptive Finite-Elemente-Simulation des Mehrfrequenz-Induktionshärtens in 3D, Härterei-Kongress, October 22 - 24, 2014, Köln, October 23, 2014.

-

TH. Petzold, Finite element simulations and experiments for multifrequency induction hardening, IUTAM Symposium on Thermomechanical-Electromagnetic Coupling in Solids: Microstructural and Stability Aspect, June 16 - 18, 2014, Paris, France, June 18, 2014.

-

TH. Petzold, Modelling and simulation of multi-frequency induction hardening of steel parts, 7th International Scientific Colloquium ``Modelling for Electromagnetic Processing'' (MEP 2014), September 16 - 19, 2014, Leibniz Universität Hannover, September 19, 2014.

-

TH. Petzold, Modelling and simulation of multifrequency induction hardening for gear components, The 18th European Conference on Mathematics for Industry 2014 (ECMI 2014), Minisymposium ``Recent Trends in Modelling, Analysis, and Simulation of Induction Heat Treatments'', June 9 - 13, 2014, Taormina, Italy, June 13, 2014.

-

D. Hömberg, Modelling and simulation of multi-frequency induction hardening, Ecole Polytechnique, Laboratoire de Mécanique des Solides, Palaiseau, France, March 13, 2014.

-

D. Hömberg, Modelling, analysis and simulation of multifrequency induction hardening, Norwegian University of Science and Technology, Department of Mathematical Sciences, Trondheim, October 21, 2014.

-

D. Hömberg, Modelling, simulation and control of surface heat treatments, Norwegian University of Science and Technology, Department of Physics, Trondheim, October 31, 2014.

-

D. Hömberg, Models of induction hardening -- An FK limited approach, RIPE60 -- Rate Independent Processes and Evolution Workshop, June 24 - 26, 2014, Prague, Czech Republic, June 25, 2014.

-

D. Hömberg, Multifrequency induction hardening --- Modelling, analysis, and simulation, Fudan University, School of Mathematical Sciences, Shanghai, China, March 4, 2014.

-

D. Hömberg, Nucleation, growth, and grain size evolution in dual phase steels, Workshop ``Recent Developments and Challenges in Interface and Free Boundary Problems'', March 25 - 28, 2014, University of Warwick, UK, March 26, 2014.

-

D. Hömberg, Nucleation, growth, and grain size evolution in dual phase steels, The 18th European Conference on Mathematics for Industry 2014 (ECMI 2014), Minisymposium 37: Simulation and Control of Hot-rolling, June 9 - 13, 2014, Taormina, Italy, June 9, 2014.

-

D. Hömberg, Nucleation, growth, and grain size evolution in dual phase steels, Wrocław University of Technology, Institute of Mathematics and Computer Science, Poland, July 1, 2014.

-

D. Hömberg, Oberflächenbearbeitung mit Mathematik, Opel Innovation Day, Rüsselsheim, November 7, 2014.

-

D. Hömberg, Optimal control and shape design problems in thermomechanics, BMS-WIAS Summer School ``Applied Analysis for Materials'', August 25 - September 5, 2014, Berlin Mathematical School, Technische Universität Berlin, September 1, 2014.

-

J. Rehberg, Maximal parabolic regularity on strange geometries and applications, Joint Meeting 2014 of the German Mathematical Society (DMV) and the Polish Mathematical Society (PTM), September 17 - 20, 2014, Adam Mickiewicz University, Faculty of Mathematics and Computer Science, Poznan, Poland, September 18, 2014.

-

TH. Petzold, Modelling and simulation of multi-frequency induction hardening of steel parts, sc Matheon Multiscale Seminar, Technische Universität Berlin, Institut für Mathematik, January 24, 2013.

-

D. Hömberg, Modelling, analysis and simulation of multifrequency induction hardening, Forum Math-for-Industry 2013 ``The Impact of Applications on Mathematics'', November 4 - 8, 2013, Kyushu University, Fukuoka, Japan, November 7, 2013.

-

TH. Petzold, Finite element simulations of induction hardening of steel parts, University of Tokyo, Graduate School of Mathematical Sciences, Japan, March 6, 2012.

-

CH. Landry, Time-optimal control for robot motion planning, Universität Bayreuth, Lehrstuhl für Ingenieurmathematik, June 6, 2011.

-

N. Togobytska, Simulation, Optimierung und Regelung von Gefügebildung und mechanischen Eigenschaften beim Warmwalzen von Mehrphasenstählen, 9. Kolloquium zum DFG SPP 1204 ``Algorithmen zur schnellen, werkstoffgerechten Prozesskettengestaltung und -analyse in der Umformtechnik'', Siegen, April 6, 2011.

-

N. Togobytska, Simulation, optimisation and control of microstructure evolution and mechanical properties during hot rolling of multiphase steels, 10. Kolloquium zum DFG SPP 1204 ``Algorithmen zur schnellen, werkstoffgerechten Prozesskettengestaltung und -analyse in der Umformtechnik'', Freiberg, November 8, 2011.

-

CH. Landry, A minimum time control problem for the collision-free robot motion planning, 82th Annual Meeting of the International Association of Applied Mathematics and Mechanics (GAMM 2011), Session on Optimal Control and Applications, April 18 - 21, 2011, Technische Universität Graz, Austria, April 20, 2011.

-

CH. Landry, A back-face culling to speed up the resolution of an optimal control problem in robot motion planning, ENUMATH 2011, September 5 - 9, 2011, University of Leicester, UK, September 5, 2011.

-

CH. Landry, Path-planning with collision avoidance in automotive industry, 25th IFIP TC 7 Conference on System Modeling and Optimization, September 12 - 16, 2011, Technische Universität Berlin, September 16, 2011.

-

CH. Landry, How to avoid collisions between translating robots, Summer School ``Optimal Control of Partial Differential Equations'', July 12 - 17, 2010, Cortona, Italy, July 15, 2010.

-

O. Rott, An iterative method for the multipliers of periodic delay-differential equations and the analysis of a PDE milling model, 9th IFAC Workshop on Time Delay Systems, June 7 - 9, 2010, Czech Technical University, Prague, Czech Republic, June 8, 2010.

-

O. Rott, Analysis of uncertainties in the stability prediction for milling processes, 2nd International Conference ``Process Machine Interactions'', June 10 - 11, 2010, The University of British Columbia, Vancouver, Canada, June 11, 2010.

-

N. Togobytska, An inverse problem for laser-induced thermotherapy arising in tumor tissue imaging, Chemnitz Symposium on Inverse Problems 2010, September 23 - 24, 2010, September 24, 2010.

-

N. Togobytska, Simulation, Optimierung und Regelung von Gefügebildung und mechanischen Eigenschaften beim Warmwalzen von Mehrphasenstählen, 8. Kolloquium zum DFG SPP 1204 ``Algorithmen zur schnellen, werkstoffgerechten Prozesskettengestaltung und -analyse in der Umformtechnik'', Aachen, November 10, 2010.

-

D. Hömberg, Coupling of process, machine, and work-piece in production processes --- A challenge for industrial mathematics, Warsaw Seminar on Industrial Mathematics (WSIM'10), March 18 - 19, 2010, Warsaw University of Technology, Poland, March 19, 2010.

-

D. Hömberg, Modelling, simulation and control of phase transformations in steel, Nippon Steel Corporation, Chiba, Japan, September 10, 2010.

-

D. Hömberg, Multiphase steels, heat treatment and distortion --- Mathematical challenges in steel production and manufacturing, Summer School ``High Performance Computing'' (organizer: TU Ilmenau), September 29 - October 2, 2010, Upstalsboom Hotel Friedrichshain, Berlin, September 30, 2010.

-

D. Hömberg, Steel manufacturing --- A challenge for applied mathematics, Universität Duisburg-Essen, Fachbereich Mathematik, May 11, 2010.

-

D. Kern, Optimal control of a thermomechanical model including transformation induced plasticity, SIAM Conference on Control and its Applications, July 6 - 8, 2009, Denver, USA, July 8, 2009.

-

N. Togobytska, Parameter identification for the phase transformations in steel, Conference on Applied Inverse Problems 2009, July 20 - 24, 2009, University of Vienna, Austria, July 21, 2009.

-

N. Togobytska, Parameter identification from dilatometric investigations, SIAM Conference on Control and its Applications, July 6 - 8, 2009, Denver, USA, July 8, 2009.

-

N. Togobytska, Simulation, Optimierung und Regelung von Gefügebildung und mechanischen Eigenschaften beim Warmwalzen von Mehrphasenstählen, 8. Kolloquium zum DFG SPP 1204 ``Algorithmen zur schnellen, werkstoffgerechten Prozesskettengestaltung und -analyse in der Umformtechnik'', WIAS Berlin, June 23, 2009.

-

D. Hömberg, Coupling of process, machine, and work-piece in production processes --- A challenge for industrial mathematics, Workshop ``Industrial Mathematics and its Practice'', February 23 - 24, 2009, University of Tokyo, Japan, February 23, 2009.

-

D. Hömberg, Die Wärmebehandlung von Stahl --- Thermomechanische Modellierung, Simulation und Optimierung, Technische Universität Dortmund, Fakultät Maschinenbau, January 22, 2009.

-

D. Hömberg, Direct and inverse problems related to phase transitions and distortion in modern multi-phase steels, Workshop ``Mathematical Models and Analytical Problems for Special Materials'', July 9 - 11, 2009, Università degli Studi di Brescia, Italy, July 9, 2009.

-

D. Hömberg, Distortion compensation --- An optimal control approach, 24th IFIP TC 7 Conference on System Modelling and Optimization, July 27 - 31, 2009, Buenos Aires, Argentina, July 27, 2009.

-

D. Hömberg, Interactions between machine, work-piece, and process dynamics in milling machines, SIAM Conference on Mathematics for Industry: Challenges and Frontiers (MI09), October 9 - 10, 2009, San Francisco, USA, October 9, 2009.

-

D. Hömberg, Optimal control of heat treatments and stability of milling processes --- Two case studies from industrial mathematics, Worcester Polytechnic Institute, Mechanical Engineering Department, USA, October 7, 2009.

-

D. Hömberg, The mathematics of distortion, University of Delaware, Department of Mathematical Sciences, Newark, USA, October 6, 2009.

-

O. Rott, A milling model with thermal effects including the dynamics of machine and workpiece, 1st International Conference on Process Machine Interactions (PMI 2008), September 3 - 4, 2008, Leibniz Universität Hannover, September 3, 2008.

-

O. Rott, Modeling, analysis and stability of milling processes including workpiece effects, The European Consortium for Mathematics in Industry (ECMI 2008), June 30 - July 4, 2008, University College, London, UK, July 3, 2008.

-

O. Rott, Numerical solution of a milling model including thermoelastic workpiece effects, Universität Dortmund, Fachbereich für Mathematik, June 23, 2008.

-

O. Rott, Parameter für ein MKS-Modell einer Fräsmaschine, DFG SPP 1180 Workshop ``Parameteridentifikation bei Werkzeugmaschinen'', February 21 - 22, 2008, WIAS Berlin, February 22, 2008.

-

O. Rott, Semiimplizite Zeitintegration eines gekoppelten Systems aus partiellen und gewöhnlichen Differentialgleichungen mit Retardierung, DFG SPP 1180 Workshop ``Modellierungstechnologien'', May 29 - 30, 2008, Dresden, May 30, 2008.

-

N. Togobytska, On the evaluation of the dilatometer experiments, Chemnitz Symposium on Inverse Problems 2008, September 25 - 26, 2008, September 25, 2008.

-

N. Togobytska, Simulation, Optimierung und Regelung von Gefügebildung und mechanischen Eigenschaften beim Warmwalzen von Mehrphasenstählen, Antragskolloquium zum DFG Schwerpunktprogramm 1204/2, Bonn, May 20, 2008.

-

W. Bleck, D. Hömberg, Ch. Keul, U. Prahl, P. Suwanpinij, N. Togobytska, Simulation, Optimierung und Regelung von Gefügebildung und mechanischen Eigenschaften beim Warmwalzen von Mehrphasenstählen, Workshop ``MEFORM 2008: Simulation von Umformprozessen'', Freiberg, March 26 - 28, 2008.

-

D. Hömberg, Modellierung und Optimierung der Gefügeumwandlung in niedrig legierten Stählen und Anwendungen, Salzgitter Mannesmann Forschung GmbH, February 19, 2008.

-

D. Hömberg, On a mathematical model for high-speed milling including the dynamics of machine and work-piece, Conference ``Direct, Inverse and Control Problems for PDE's'' (DICOP 08), September 22 - 26, 2008, Cortona, Italy, September 26, 2008.

-

D. Hömberg, Prozesskette Stahl, Workshop of scshape Matheon with Siemens AG (Industry Sector) in cooperation with Center of Knowledge Interchange (CKI) of Technische Universität (TU) Berlin and Siemens AG, TU Berlin, September 29, 2008.

-

D. Hömberg, Solid-solid phase transitions --- Analysis, optimal control and industrial application, Warsaw University of Technology, Faculty of Mathematics and Information Science, Poland, February 14, 2008.

-

D. Hömberg, The heat treatment of steel --- A mathematical control problem, 2nd International Conference on Distortion Engineering 2008, September 17 - 19, 2008, Bremen, September 19, 2008.

-

D. Kern, Optimal control of a thermo-mechanical model of phase transitions in steel, 13th Czech-French-German Conference on Optimization, September 17 - 21, 2007, Heidelberg, September 20, 2007.

-

W. Weiss, Control of laser surface hardening, 6th International Congress on Industrial and Applied Mathematics (ICIAM 2007), July 16 - 20, 2007, ETH Zürich, Switzerland, July 19, 2007.

-

W. Weiss, Simulationsbasierte Regelung der Laserhärtung von Stahl, Ruhr-Universität Bochum, Institut für Werkstoffe, May 30, 2007.

-

D. Hömberg, D. Kern, Optimal control of a thermomechanical model of phase transitions in steel, 6th International Congress on Industrial and Applied Mathematics (ICIAM 2007), July 16 - 20, 2007, ETH Zürich, Switzerland, July 19, 2007.

-

D. Hömberg, Mathematical tools for the simulation and control of heat treatments, Delphi, Puerto Real, Spain, January 16, 2007.

-

D. Hömberg, Mathematics for complex production processes, Comau, Turin, Italy, March 23, 2007.

-

D. Hömberg, Mathematics for steel production and manufacturing, Nippon Steel, Kimitsu, Japan, March 1, 2007.

-

D. Hömberg, On a thermomechanical phase transition model for the heat treatment of steel, Universidad de Cádiz, Departamento de Matemáticas, Puerto Real, Spain, January 15, 2007.

-

D. Hömberg, On a thermomechanical phase transition model for the heat treatment of steel, Fudan University, Department of Mathematics, Shanghai, China, March 5, 2007.

-

D. Hömberg, Optimal control of semilinear parabolic equations and an application to laser material treatments (part I), University of Tokyo, Department of Mathematical Sciences, Japan, February 21, 2007.

-